- Official BOC UK Online | Industrial Gases | Products & Solutions | BOConline UK

-

Shop

- Industries

- Processes

- Gases & Equipment

-

Solutions

-

Services

-

Health & Safety

-

Contact & Support

- What's Happening

-

Net Zero Strategies

How Does a Hydrogen Refuelling Station Work?

Posted by BOC

The UK set out an ambitious Hydrogen Strategy in 2021 which emphasises the important role that hydrogen will have in reaching net zero. Now we need to turn that plan into reality. Green hydrogen has the potential to supercharge decarbonisation, but global cooperation at many levels will be needed to foster this development. Many have rightly identified this energy vector as the most feasible way to decarbonise the harder to abate sectors – especially transportation.

For hydrogen to be truly green, it needs to be created through electrolysis, using electricity from renewable sources. Energy from wind and solar is channelled into an electrolyser and used to split water molecules into their component elements – hydrogen and oxygen. But while most of us are familiar with refuelling a car, or re-charging an electrical appliance, hydrogen vehicle refuelling is a less familiar process. So how does it work?

What equipment does a hydrogen refuelling station need?

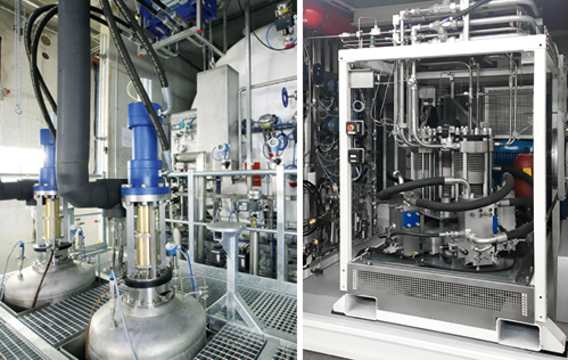

Hydrogen dispensers can sit alongside petrol and diesel pumps, but independent hydrogen refuelling stations (HRS) are already in use in countries around the world. Unlike a petrol station, a HRS can either generate its own gas with an onsite electrolyser or have hydrogen delivered to site. However, they do have some specific requirements. These include hydrogen storage facilities, compressors to bring the hydrogen to the desired pressure level, which is 700 bar for cars and 350 bars for larger vehicles such as buses or refuse vehicles, high or medium intermediate pressure storage, a precooling system, and safe dispensers for delivering the fuel.

Filling the tank

Refuelling with hydrogen is a familiar process, just like refuelling with petrol or diesel, and much faster than charging an electric vehicle. It takes around 12 minutes to refuel a bus, giving a range of around 350km, and 5 minutes for a car enabling a range of 400 miles. Once fuelled, the vehicle emits zero emissions – just clean water from the tail pipe. Like a battery electric vehicle, a hydrogen vehicle is virtually noiseless.

You’ll usually start your refuelling process by following the step-by-step guide on the display, and securely attaching the nozzle to your vehicle’s refuelling point. A special refrigeration unit within the dispenser then cools the hydrogen to -40℃ before pumping it through the nozzle and into your vehicle. Once this is done, the station automatically refills the high-pressure storage tanks ready for the next vehicle.

Safety, reliability, and future proofing

Safety is always a top priority and it is important to ensure that a HRS is located an appropriate distance from nearby assets, such as buildings or equipment. Our hydrogen storage vessels are purpose-built to maintain pressures at optimal, safe levels and our dispensers are designed to ensure a safe connection between the nozzle and vehicle – with effective system safety checks every time they are used. Sophisticated leak detection technology automatically shuts down the plant should any hydrogen escape.

Another key requirement for any refuelling infrastructure is reliability – especially when a large area is dependent on access to a single refuelling station for all its needs. This has been proven at the Kittybrewster refuelling station in Aberdeen. Here, every refuelling has been successful since the station’s launch in 2015, and the HRS has a reliability rate of 99.5%.

As adoption of hydrogen fuelled vehicles becomes more widespread, demand will inevitably grow. Our modular design for fuelling stations enables them to be scaled up to match the growing needs of users.

Established, proven technology

Vehicles are already refuelling with hydrogen daily across the UK. Councils and local transport authorities (LTAs) are leading the way by updating transport fleets to zero emissions vehicles and putting the infrastructure in place to enable others to follow suit.

Aberdeen City Council, for example, worked with us to develop, install, and operate a tailored, state-of-the-art hydrogen refuelling station. The facility, based at the Kittybrewster bus depot, produces green hydrogen from electrolysis on site, and supplies a fleet of buses that travel up to 350km each day. Kittybrewster is now accessible to all hydrogen-fuelled vehicles, including double decker buses and private vehicles.

We are working with councils and transport operators to create new green hydrogen production facilities and clusters of refuelling stations across Scotland and the UK – supporting the country’s efforts to achieve net zero.